Work

Creating the starting point for all products

Based on the product data we receive from the customer, we create designs which give consideration to such factors as the feasibility, strength and the ease of maintenance of mold structures, and carry out modelling work using 3D and CAD. Learning from technical diagrams is the first step of design. You can learn about the structure of molds through diagrams used in the assembly of molds and by creating a range of diagrams which show the structure. Once you master modelling work, you will be able to accomplish fully-fledged design work.

Growth

Designs with a solid grounding are a sign of growth

I really felt I had grown when I was able to finally understand mold structures, as well as when I created a well-grounded design on my own initiative. I was especially happy in my third year at the company when for the first time I successfully removed a molded product from a mold I had designed from scratch.

Goal

Increasing one’s knowledge in an effort to reach the next stage

To be able to state your own opinions and engage in discussions at internal and external company meetings. I am not at this level yet, so what I need to focus on at the moment is to increase my knowledge of mold structures. I will keep working to make improvements and work more efficiently.

Machinery Division’s Work

Aiming at accurate operations by relying on diagrams

I am in charge of operations at the machining center for processing iron. I set the materials according to the program for the product, and if necessary, also revise the program to the best of my ability. I have to deal with multiple machines, so remembering how to operate them was tough. Today, I am again focusing on keeping up with the work load.

Growth

Past experiences as the seeds for growth

Recently, I learned how to operate new machines and am now able to do more things. When malfunctions or other problems occur with the machines, I am able to draw on my past experiences and solve the issues by myself without asking one of my superiors. It is things like this that make me realize I have grown as an employee.

Goal

Understanding the entire manufacturing process is something that would make work even more rewarding.

I am only involved in some of the processes at the moment, but I would like to experience assembly, etc., which would give me more of an understanding of the entire mold manufacturing process. Learning about that would make my work even more interesting and rewarding.

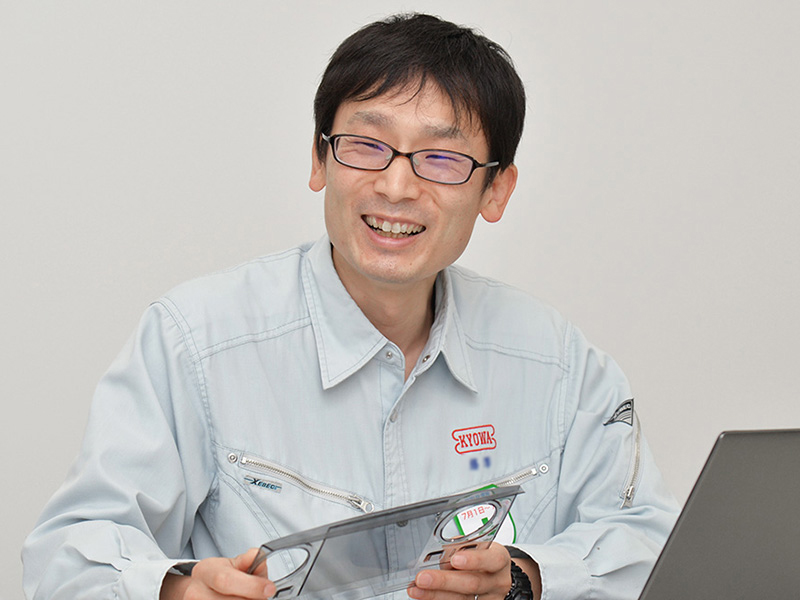

Trial Production Division’s Work

Controlling all kinds of molding conditions

Setting the completed mold on the molding machine, and operating it under the actual conditions for mass production, and confirm the molds and plastic parts run perfectly. This series of tasks is performed under the watchful eye of customers who are present. Our prototype production facilities are some of the most extensive of their kind in Japan, and I have mastered how to operate almost all the machines and am able to deal with all kinds of scenarios.

Growth

Feeling a sense of one’s own growth by not repeating the same mistakes

At first, I did everything from preparing molds to cleaning up with the help of my superiors, but I have gradually come to be able to do things by myself. I feel with my experience at this point, I have stopped repeating the same mistakes.

Goal

Aiming to create better molding conditions

I hope to be able to stand on my own two feet as soon as possible, and be a useful member of society as a member of the Prototype Division. My goal is to master how to operate all machines and be able to produce better molding conditions from the start.

Sales Division’s Work

Providing total support, from design proposals to follow-up services

Total support that goes beyond selling finished products to customers, from the initial stage of drawing up diagrams to the delivery of detailed design proposals to customers and follow-up support after delivery. It is the work of those in sales jobs to provide this string of services. Soon after joining the company, I went to Aichi Prefecture for five years, where I learned a lot in Japan’s no. 1 manufacturing region and grew as a person. Today, I continue to maintain good business relations with customers from those days.

Growth

Efforts to deepen one’s knowledge as a means of self-growth

Initially, I did not even know the names of parts, and I was a burden to others. To overcome this situation, I decided not only just to do the things I was asked to, but to also see things through until I was truly satisfied. This helped me gain a deep knowledge of my work, and enabled me to talk with people from both inside and outside the company on an even footing.

Goal

Contributing to society through exceptional technological capabilities

“Provide help so that the future feels like it is just around the corner.” These were the words of our President. By linking our technologies with the requests of customers, we may be able to help create a more fulfilling life for all. That is why my goal is to contribute to society through technology.